Story: Lisa Sollie | Photo: Kay Lucas

On game days at Tiger Stadium in Livingston, Alabama, the inside of the University of West Alabama’s mascot, LUie the Tiger, gets hot. Thanks to three UWA engineering technology graduates, however, a cool solution is now within reach.

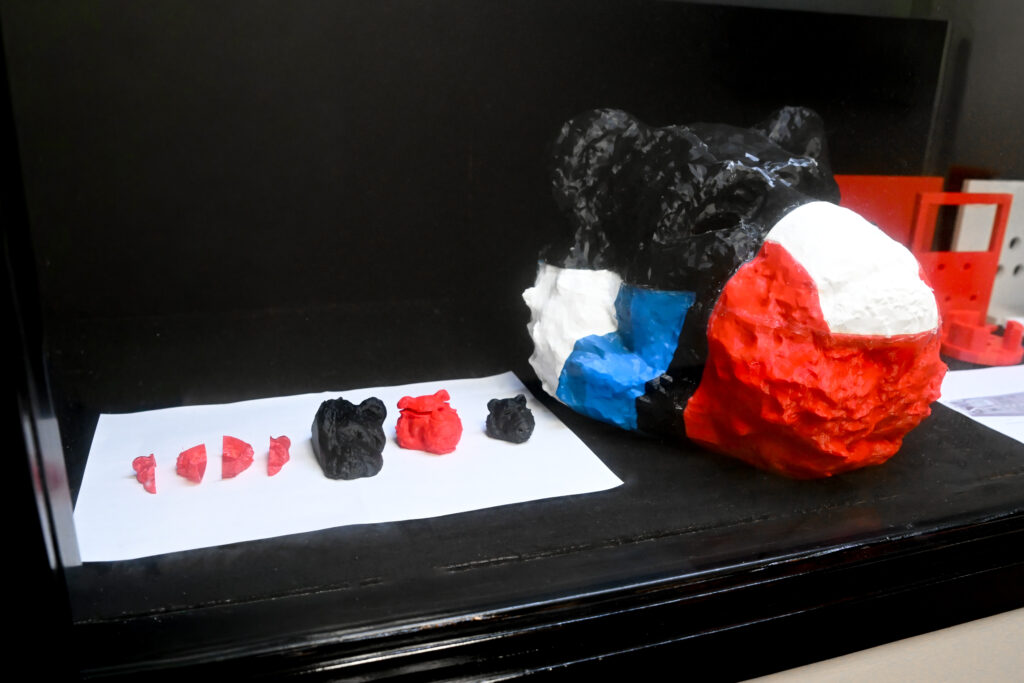

Last spring, then-seniors Matthew Mosley, Tyler Lovering, and Ishmael Naylor designed a high-tech prototype mascot head for their senior capstone project. Their innovative design featured an integrated cooling system, improved ventilation, and a lightweight structure, all aimed at making mascot duty more comfortable in the Alabama heat.

Dr. Narendra Datta, chair of the Division of Engineering Technology, explains that the annual capstone project challenges seniors to develop real-world, hands-on projects integrating everything they’ve learned throughout their degree program. Guided by Dr. Datta, Mosley, Lovering, and Naylor selected this unique project topic.

Assistant professor Robert Miller provided valuable support to the team and Naylor, who led the initial phase of scanning LUie’s existing mascot head and importing the model into Fusion 360, the AutoCAD software used in their coursework. The team then integrated a compact water-to-water cooling system using a hydration vest, tubing, and a mini water pump, applying principles of fluid power, heat transfer, and motor controls.

Lovering focused on heat transfer calculations and conducted temperature reduction tests to validate the prototype’s effectiveness. The team also replaced the internal helmet with an adjustable hard hat for better fit and enhanced ventilation, while enlarging the eye openings for improved visibility. Tests showed the prototype lowered internal temperatures by 5–7°F.

Mosley managed the project timeline, ensuring tasks were completed on time and parts were ordered on schedule.

“This project used many skills I developed over my four years at UWA,” Mosley says. “Project management provided a blueprint that helped me plan, prepare and organize our project, while computer applications like Excel kept our materials and progress in order. Our engineering courses supported the design and mathematical aspects of the project.”

Since graduating in May, Naylor has worked for Steel Dynamics’ Columbus Division in Mississippi, starting as an electrical engineering intern and moving to a full-time position as a millwright technician by August. He credits UWA’s engineering technology program for thoroughly preparing him for his career.

“I can’t say enough about the excellent instruction from Datta and our professors and instructors,” Naylor shares. “They genuinely care about our success, combining classroom learning with hands-on labs that give us the practical experience we need on the job. Our senior project proved we have what it takes to succeed in any challenge.”

Mosley, now a mechanical engineer at Phifer, Inc. in Tuscaloosa, Alabama, echoes this sentiment. “At Phifer I handle projects from design to repair, creating drawings and ordering parts, then leading maintenance crews during installation. My drafting and mechanical motor classes have been invaluable in these tasks.

Although the prototype isn’t ready for permanent use, Datta believes their work showcases the students’ creativity and ability to apply engineering principles to practical challenges at the University. Building on their success, a new senior team, guided by Datta, Miller and assistant professor Dr. Ikechi Ukaegbu, will explore new materials to enhance durability without sacrificing cooling efficiency.

“We intend to continue this project with future senior teams, allowing each group to build on the work of the last,” Datta says. “This ongoing effort will drive the development of a more comfortable mascot head for LUie, creating a lasting legacy of innovation and student achievement.”